Empowering Engineering Excellence: Innovate, Elevate, Deliver.

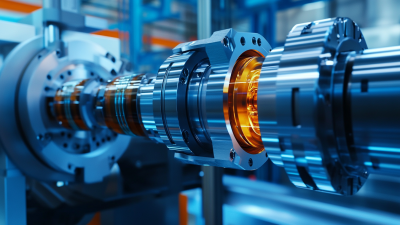

When it comes to selecting the best small hydraulic cylinder for your application, the process can often feel overwhelming due to the multitude of options available in the market. Small hydraulic cylinders are essential components in various industries, providing reliable force in tight spaces and contributing significantly to the efficiency of machinery.

Whether you are working on a compact manufacturing setup, a robotic application, or other specialized equipment, understanding the unique specifications, materials, and performance characteristics of small hydraulic cylinders is crucial. This essential checklist aims to guide you through the selection process, helping you make an informed decision that aligns with your specific needs and project requirements.

By paying attention to key factors, you can ensure that you choose a hydraulic cylinder that not only meets your operational demands but also stands the test of time.

When selecting the best small hydraulic cylinder, understanding your application requirements is crucial. The global hydraulic cylinder market is experiencing significant growth, with an estimated worth of USD 14.3 billion in 2021, expected to reach USD 18.3 billion by 2027. This expansion highlights the increasing demand for hydraulic solutions across various industries, making it essential to identify the specific needs of your application to choose the most suitable cylinder.

Key factors to consider include the operating environment, load capacity, and available space. Hydraulic cylinders are often exposed to challenging conditions, and their performance can be affected by factors such as temperature fluctuations and the presence of different fluids. As seal manufacturers innovate to create materials that can withstand these tough environments, their importance in the overall efficiency and durability of hydraulic systems cannot be overstated. By closely examining the requirements of your application and the latest advancements in sealing technology, you can ensure that you select a small hydraulic cylinder that meets your operational needs effectively.

When selecting a small hydraulic cylinder, several key specifications play a crucial role in ensuring optimal performance and compatibility with your application. One of the primary factors to consider is the cylinder's bore size, which typically ranges from 1.5 inches to 4 inches for small hydraulic cylinders. According to the Hydraulic Cylinder Market Analysis by Grand View Research, the demand for compact hydraulic solutions is expected to grow by 5.5% annually, signifying the importance of choosing the right bore size to match your system's force requirements.

Another critical specification is the stroke length, which can vary based on the intended application. Short stroke cylinders are ideal for applications with limited space, while those that require extended reach should consider longer strokes. Data from MarketsandMarkets indicates that custom stroke lengths are increasingly popular due to the need for tailored solutions in various industries. Additionally, the choice of material and sealing technology should not be overlooked; selecting high-quality materials and advanced sealing systems can significantly affect durability and efficiency, leading to a longer lifecycle and reduced maintenance costs.

| Specification | Description |

|---|---|

| Bore Diameter | The internal diameter of the cylinder, impacting the force output. |

| Stroke Length | The length that the piston can move within the cylinder, determining the range of motion. |

| Operating Pressure | The maximum pressure the cylinder can operate under, affecting performance and safety. |

| Mounting Style | Types of mounts available (e.g., flange, rod end), critical for installation compatibility. |

| Cylinder Material | Material used (e.g., steel, aluminum), influencing durability and weight. |

| Seal Type | Type of seals used within the cylinder affecting leak resistance and maintenance.< /td> |

| Temperature Range | The temperature range within which the cylinder can operate effectively. |

| Weight | The weight of the cylinder, which can affect overall system design and portability. |

| Cycle Rate | The speed at which the cylinder can cycle, important for efficient operation. |

When selecting a small hydraulic cylinder, one crucial factor to consider is the material from which it is made. The durability of the cylinder is largely influenced by the material's resistance to wear, corrosion, and environmental conditions. For instance, options like stainless steel and aluminum are popular choices due to their strength and ability to withstand harsh conditions, making them ideal for outdoor applications. Additionally, high corrosion-resistant coatings can significantly enhance the longevity of the cylinders, especially in marine environments or industries where moisture is prevalent.

Another important material consideration is the internal design of the hydraulic cylinder. Components such as piston rods and seals must also be made from durable materials to ensure efficient operation and longevity. For applications in precision machining or heavy workloads, investing in a cylinder made from high-quality materials can prevent failures and reduce maintenance costs over time. Overall, understanding the material options and their respective benefits will help you choose the best small hydraulic cylinder to meet your specific needs in various applications.

When selecting a small hydraulic cylinder, evaluating performance factors is crucial to ensure optimal functionality and reliability. One of the primary considerations is the working pressure, which can greatly affect the cylinder's efficiency. According to a report by the National Fluid Power Association (NFPA), hydraulic cylinders typically operate at pressures between 1,500 to 3,000 psi for small-scale applications. Understanding the pressure limits and how they align with your specific application can prevent premature wear and potential failures.

Another essential performance factor is the cylinder's stroke length. The stroke length often determines the range of motion required for your application. Research by the Fluid Power Journal highlights that cylinders with adjustable stroke lengths are becoming increasingly popular, allowing for greater versatility in design and performance. Moreover, factors such as rod diameter and material choice significantly influence the cylinder’s strength and lifespan. The Hydraulic Industry Association (HIA) suggests that selecting the right material, typically high-strength steel or aluminum, can enhance performance and reduce the risk of fatigue under repetitive loads.

Additionally, the speed of the hydraulic cylinder's operation should not be overlooked. The average cycle time for a hydraulic system can vary significantly, with faster stroke speeds leading to increased efficiency. For instance, the latest advancements in hydraulic technology have seen operational speeds rise up to 25 inches per second, as noted in a study from the American Society of Mechanical Engineers (ASME). Therefore, thoroughly evaluating these performance metrics will ensure you select a small hydraulic cylinder that not only meets but exceeds your operational requirements.

When it comes to maintaining hydraulic cylinders, proper upkeep is essential for extending their lifespan and ensuring optimal performance. Regular maintenance not only prevents unexpected failures but also enhances safety in any operational setting. One crucial step in this maintenance routine is regularly checking and replacing hydraulic fluid. Contaminants in the fluid can lead to wear and tear on cylinder components, significantly reducing efficiency and reliability.

Another important aspect is the integration of modern technologies to facilitate predictive maintenance. Utilizing sensors and monitoring systems can help track the condition of hydraulic cylinders in real-time, allowing for timely interventions before issues escalate. This proactive approach minimizes unplanned downtime and prolongs the operational life of your hydraulic equipment.

Lastly, cleanliness cannot be overlooked. Keeping hydraulic systems free of debris and contaminants is vital for maintaining functionality. Implementing a flushing procedure as a routine maintenance task can protect against fluid contamination, ensuring smooth operation and extending the life of hydraulic cylinders. Adopting these maintenance tips will not only enhance the performance of your hydraulic systems but also provide long-term savings by reducing the frequency of repairs and replacements.