Empowering Engineering Excellence: Innovate, Elevate, Deliver.

The global market for hydraulic tools, including the Hydraulic Bearing Puller, is witnessing remarkable growth, driven by advancements in manufacturing technologies and increasing demand across various industries. According to a recent industry report, the hydraulic tools market is projected to reach $15 billion by 2026, with a compound annual growth rate (CAGR) of 5.7%. As industries such as automotive, aerospace, and heavy machinery continue to expand, the need for efficient and reliable tools becomes paramount. The Hydraulic Bearing Puller stands out as a critical piece of equipment, enabling technicians to perform complex tasks with precision and ease. With China emerging as a leader in hydraulic tool production, its innovations are setting new benchmarks for quality standards globally. This blog will explore how the Hydraulic Bearing Puller crafted in China not only meets but pioneers these quality standards, ultimately enhancing operational efficiency for businesses around the world.

The hydraulic bearing puller, a vital tool in mechanical repair and maintenance, has undergone significant transformation with the rise of Chinese innovation. Historically, this tool was synonymous with labor-intensive designs; however, China has revolutionized its functionality and efficiency. Recent reports indicate that the global market for hydraulic tools is projected to reach approximately $5 billion by 2027, driven in large part by advancements in hydraulic technology from innovators in China.

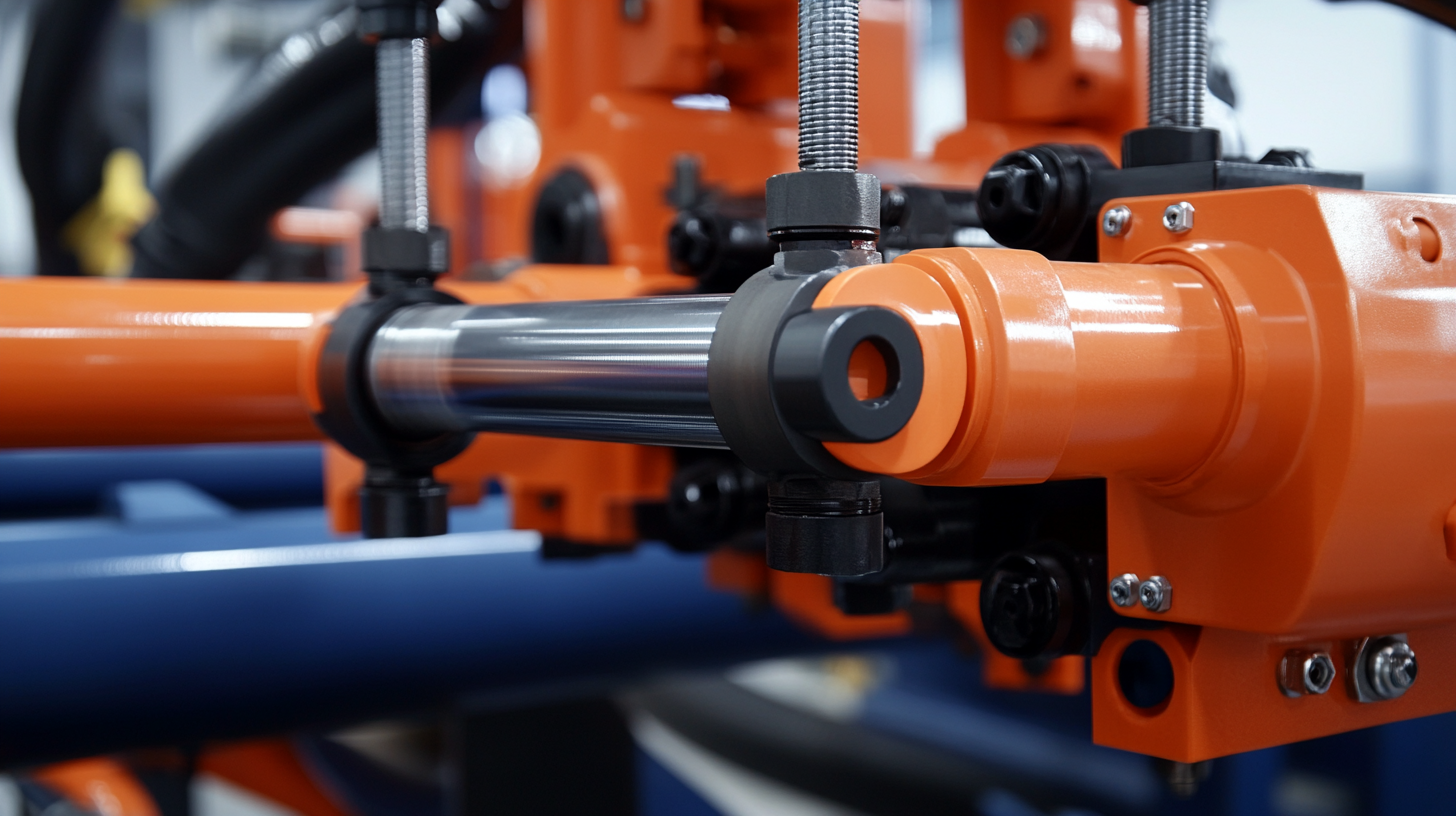

Chinese manufacturers have made significant strides, not just in quantity but also in quality, pushing boundaries that were once thought unattainable. Enhanced precision engineering and the integration of innovative materials have allowed for lighter, more durable pullers that outperform traditional counterparts. As Chinese universities and companies continue to collaborate, the emphasis on research and development has elevated the standards of hydraulic bearing pullers, showcasing a commitment to excellence that is capturing attention on the world stage. With China rapidly evolving into a leading force in advanced industries, the hydraulic bearing puller exemplifies the nation's capacity for innovation and its potential to redefine global quality standards.

This bar chart illustrates the growth of the global market share of hydraulic bearing pullers crafted in China from 2000 to 2023, showcasing the remarkable evolution and innovation in this industry.

Manufacturing quality standards have become a significant focus in global industries, and China is emerging as a leader in this realm. The country's commitment to enhancing quality in products, particularly in complex machinery like hydraulic bearing pullers, showcases its ability to set high benchmarks. This evolution is propelled by advanced technologies and rigorous testing protocols that ensure every component meets international quality requirements.

Chinese manufacturers are increasingly adopting best practices from around the world while integrating local innovations. This blend not only optimizes production processes but also reinforces the assurance of quality. As Chinese hydraulic bearing pullers gain recognition for their reliability and performance, they help redefine perceptions of manufacturing standards in the global market. By investing in continuous improvement and adhering to stringent regulations, China is paving the way for elevated quality standards that resonate across various industries worldwide.

The landscape of hydraulic tools is witnessing a transformative era marked by significant advancements in design and efficiency. Recent collaborations, such as the one between HydraForce and SaMASZ, demonstrate how hydraulic system redesigns can lead to enhanced performance in agricultural equipment. The development of a new tractor-mounted disc mower exemplifies the integration of innovative hydraulic solutions that not only improve operational efficiency but also meet the evolving demands of the agricultural sector.

At upcoming exhibitions like bauma 2025, hydraulics companies will showcase cutting-edge technologies aimed at increasing performance and efficiency across various industries. The focus will be on how electrification and automation are revolutionizing mobile machinery, driving the need for more sophisticated hydraulic systems. Additionally, the innovation in filter designs for fluid power systems underscores a shift towards sustainable and durable components that protect against contamination, further enhancing the overall effectiveness of hydraulic tools. These advancements reflect a broader trend where the industry is striving to meet the dual challenges of efficiency and sustainability.

The global market for hydraulic bearing pullers is witnessing a significant shift, largely driven by the emergence of China as a leading innovator in advanced manufacturing industries. With improved technological capabilities and a focus on research and development, Chinese manufacturers are setting new quality standards that resonate well with international buyers. This evolution reflects a broader trend where China is no longer seen merely as a production hub but as a pivotal player redefining quality benchmarks in the global market.

As reported, the tube puller market is projected to grow at a 4.7% CAGR, reaching a substantial $235 million by 2034. This growth is a testament to the increasing reliance on advanced tools and equipment across various sectors, including automotive and machinery. Chinese hydraulic bearing pullers are increasingly becoming the preferred choice due to their innovative designs and enhanced performance, showcasing the country's ability to merge quality with affordability. As they continue to gain traction globally, these products not only highlight the manufacturing prowess of China but also signify its commitment to setting and meeting international standards in the industry.

In the realm of manufacturing and maintenance, hydraulic bearing pullers have emerged as indispensable tools across various industries. Aimed at enhancing operational efficiency, these pullers are designed to handle challenging extraction tasks with precision and power. According to a report by MarketsandMarkets, the global hydraulic tools market is projected to reach USD 4.5 billion by 2026, indicating a robust demand for tools like hydraulic pullers. This growth is largely driven by the expansion of the automotive and aerospace sectors, where reliable equipment is critical for rapid production and maintenance cycles.

One notable success story comes from the automotive industry, where a leading manufacturer implemented hydraulic bearing pullers to streamline its assembly line. The use of these tools reduced downtime by 25%, allowing for a more efficient workflow and significant cost savings. In another case, a heavy machinery company reported a decrease in maintenance-related accidents by 30% after adopting hydraulic pullers, enhancing not only productivity but also workplace safety. These examples illustrate how hydraulic pullers not only elevate quality standards but also contribute to a safer and more efficient industrial environment.