Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In today's rapidly evolving manufacturing landscape, the integration of advanced machinery is paramount to staying competitive. Among these innovations, the Hydraulic Press has emerged as a transformative force, redefining efficiency and productivity across various sectors. According to a report by Markets and Markets, the global hydraulic press market is projected to reach $4.7 billion by 2025, driven by the demand for enhanced operational capabilities and automation in manufacturing processes. By harnessing the immense power and precision offered by hydraulic technology, manufacturers are not only streamlining production but also reducing energy consumption and waste, further aligning with sustainability goals. This blog explores the seven compelling reasons why Hydraulic Presses are revolutionizing manufacturing processes, setting a new standard for quality and efficiency in the industry.

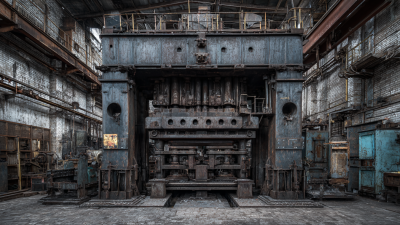

The evolution of manufacturing has been marked by significant technological advancements, with hydraulic presses standing out as a game changer in production dynamics. These powerful machines leverage hydraulic force to manipulate materials, allowing manufacturers to achieve precision and efficiency that traditional methods cannot match. This transformation enables industries to streamline operations, reduce costs, and enhance the quality of their products. Hydraulic presses not only replace manual methods but also integrate seamlessly into automated production lines, fostering a new era of manufacturing where speed and accuracy are paramount.

Additionally, the versatility of hydraulic presses makes them invaluable across various sectors, including automotive, aerospace, and metal fabrication. They can effortlessly perform diverse tasks such as stamping, molding, and assembling, adapting easily to different materials and production requirements. As manufacturers strive for ever-increasing output and product complexity, the ability to maintain consistency and repeatability with hydraulic technology becomes crucial. This evolution is not just about machinery; it signifies a shift in how industries approach production, ultimately leading to innovative products and more efficient manufacturing processes.

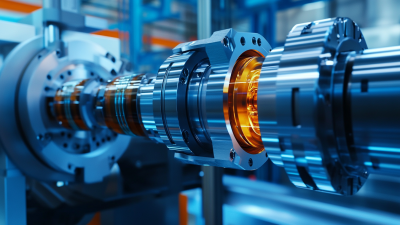

Hydraulic presses have become essential tools in modern manufacturing, significantly enhancing efficiency and output. One of the key advancements in hydraulic technology is the incorporation of computer-controlled systems, which allow for precise adjustments and real-time monitoring. This level of control ensures that every stroke is optimized for the material being processed, leading to minimal waste and maximum productivity. As industries face increasing demand for faster production times, hydraulic presses rise to the occasion by streamlining operations and reducing downtime.

Moreover, the ability of hydraulic presses to apply consistent pressure across various materials means less variability in product quality. Manufacturers can achieve finer tolerances and better finishes, resulting in reduced need for secondary operations. This efficiency not only saves time but also conserves resources, making it a sustainable choice for businesses looking to reduce their environmental footprint. With the integration of hydraulic technology, manufacturers can meet consumer demands without compromising on quality, thereby revolutionizing the entire manufacturing landscape.

In the realm of precision engineering, achieving unmatched accuracy in manufacturing tasks is paramount. Recent advancements have illustrated how tools such as metrology-grade scanners are playing a critical role in ensuring that manufacturing processes meet the highest standards. For instance, automated robots are now deployed in various sectors, effectively managing tasks that require precision, such as pick-and-place operations in warehouses. This transition not only enhances productivity but also maintains, and even improves, quality control across the board—factors that are vital in today's fast-paced production environments.

Moreover, the integration of advanced metrology technologies is transforming how manufacturers establish and verify accuracy. The ability to achieve sub-micron precision with advanced hexapod systems exemplifies this shift, allowing industries to operate continuously while ensuring reliability and accuracy in their work. According to industry reports, the global market for precision manufacturing is projected to grow significantly, reflecting diminishing tolerances that modern manufacturing equipment must achieve. In this competitive landscape, hydraulic presses not only facilitate efficient production but also align seamlessly with these cutting-edge metrology techniques, paving the way for innovations that drive the future of manufacturing.

In today's competitive manufacturing landscape, hydraulic presses stand out as pivotal tools for enhancing cost-effectiveness. By optimizing production processes, these machines not only boost operational efficiency but also significantly reduce overhead costs. With advancements in energy efficiency, modern hydraulic presses have become more sustainable options, allowing manufacturers to decrease energy consumption while maintaining high productivity levels. Such innovations are particularly relevant given the growing focus on resource efficiency across various industries, including oilfield services, projected to expand to a market value of $232.09 billion by 2032.

Moreover, the integration of hydraulic presses in manufacturing aligns perfectly with the trends towards sustainability and resilience. As industries explore decentralized systems for resource management, hydraulic solutions can play a crucial role in minimizing environmental impacts. For example, by employing energy optimization methodologies in hydraulic press operations, manufacturers can not only cut costs but also contribute to broader sustainability goals. This dual benefit reinforces the potential of hydraulic presses to revolutionize manufacturing processes, making them indispensable for future-ready production environments.

Hydraulic presses have become a pivotal force in modern manufacturing, showcasing remarkable versatility across various industries. From automotive to construction, the adaptability of hydraulic presses enables them to perform a multitude of tasks ranging from shaping, molding, and assembly to piercing and stamping. This universal application not only enhances operational efficiency but also significantly reduces production time, allowing manufacturers to respond swiftly to market demands.

The projected growth of the global metal forming tools market signifies a robust interest in advanced technologies like hydraulic presses. With the market estimated to increase from $29.41 billion in 2025 to $51.67 billion by 2032, industries are increasingly recognizing the cost-effectiveness and precision that hydraulic power brings to their processes. Furthermore, the expanding hydraulic power packs market—supporting diverse end-user sectors—exemplifies the ongoing evolution and integration of hydraulic technology. As manufacturers continue to seek innovative solutions, hydraulic presses stand out as a versatile and essential tool in bolstering production capabilities across the board.

| Application Area | Key Benefits | Typical Pressure Range | Industries Utilized |

|---|---|---|---|

| Metal Stamping | High precision and repeatability | 50 to 1500 tons | Automotive, Aerospace |

| Plastic Molding | Versatility in designs and sizes | 10 to 2000 tons | Consumer Goods, Electronics |

| Composite Materials | Enhanced strength and lightweight structures | 20 to 1000 tons | Aerospace, Sports Equipment |

| Woodworking | Efficient bonding and shaping of materials | 5 to 200 tons | Construction, Furniture Manufacturing |

| Textile Pressing | Improved fabric finishing and shaping | 10 to 500 tons | Apparel, Home Textiles |

| Food Processing | Extraction and production efficiency | 1 to 100 tons | Beverage, Packaged Foods |

| Jewelry Manufacturing | Precision shaping and forming of metals | 0.5 to 10 tons | Jewelry, Artisans |