Empowering Engineering Excellence: Innovate, Elevate, Deliver.

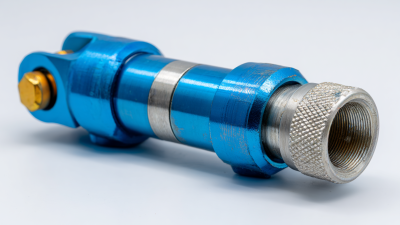

In the ever-evolving landscape of industrial tools, hydraulic jacks have emerged as indispensable devices for various applications, offering unique advantages in terms of lifting capacity and precision. As global suppliers seek innovative solutions to meet the demands of diverse industries, the role of hydraulic jacks has expanded beyond traditional use cases.

From automotive repair to heavy construction, these powerful mechanisms enable efficient and safe lifting operations, significantly enhancing productivity and safety standards.

This blog will explore the innovative uses and applications of hydraulic jacks, spotlighting how leading suppliers are leveraging these tools to drive efficiency and effectiveness across multiple sectors.

By examining the latest advancements and creative approaches, we aim to provide valuable insights into the transformative impact of hydraulic jacks in modern industry.

From automotive repair to heavy construction, these powerful mechanisms enable efficient and safe lifting operations, significantly enhancing productivity and safety standards.

This blog will explore the innovative uses and applications of hydraulic jacks, spotlighting how leading suppliers are leveraging these tools to drive efficiency and effectiveness across multiple sectors.

By examining the latest advancements and creative approaches, we aim to provide valuable insights into the transformative impact of hydraulic jacks in modern industry.

The hydraulic jack industry is witnessing exciting advancements that are reshaping its applications across various sectors. Emerging trends in hydraulic jack technologies highlight the integration of smart systems and automation, making them increasingly efficient and user-friendly. For instance, the incorporation of IoT sensors allows for real-time monitoring and diagnostics, ensuring optimal performance and enhancing safety during heavy lifting operations. This technology not only streamlines maintenance but also minimizes downtime, which is critical for suppliers looking to improve operational efficiency.

Another significant trend is the development of more compact and lightweight hydraulic jacks without compromising their lifting capacity. Innovations in materials and engineering have resulted in jacks that are easier to handle and transport, catering to the growing demand for portable solutions in the automotive, construction, and manufacturing industries. As global suppliers adapt to these advancements, they can offer their clients enhanced products capable of meeting the challenges of modern applications, paving the way for increased productivity and cost-effectiveness in various operations.

| Application Area | Innovative Use | Emerging Trend | Industry Impact |

|---|---|---|---|

| Automotive Repair | Self-leveling hydraulic jacks that adjust based on load | Increased safety and efficiency in lifting | Reduces technician injury and enhances repair speed |

| Construction | Portable hydraulic jacks for quick lifting of heavy materials | Use of lightweight materials in jack design | Improves mobility and reduces transport costs |

| Aerospace | Advanced hydraulic systems for aircraft maintenance | Smart jacks with pressure sensors | Enhances precision in servicing and reduces ground time |

| Marine | Hydraulic jacks for boat lifts and dry-docking | Integration with IoT for monitoring and control | Improves efficiency and reduces maintenance costs |

| Manufacturing | Automated hydraulic jacks in production lines | Robotic integration for precise handling | Boosts productivity and reduces human error |

Hydraulic jacks are increasingly becoming indispensable tools across various industries due to their versatility and efficiency in lifting heavy loads. In the automotive sector, for example, the global hydraulic jacks market is projected to grow at a CAGR of 4.2% from 2021 to 2026, highlighting their relevance for vehicle maintenance and repair. These jacks enable mechanics to easily lift cars for tire changes, brake repairs, and engine work, contributing to better service turnaround times and enhanced safety standards in workshops.

In the construction industry, hydraulic jacks play a critical role in lifting structures during foundation work and heavy-duty lifting tasks. According to a report by Market Research Future, the construction segment is expected to account for over 30% of the hydraulic jacks market share by 2025. Their ability to handle substantial weight with precision makes them suitable for both large-scale projects and small renovations, allowing contractors to optimize productivity while ensuring worker safety. Furthermore, the emergence of portable hydraulic jacks has expanded their application in other fields like shipbuilding and manufacturing, reinforcing their value across diverse sectors.

Hydraulic jacks are invaluable tools that have evolved significantly, with innovative designs maximizing efficiency across various industries. These advanced devices not only streamline lifting processes but also enhance safety and reduce the physical strain on operators. Modern hydraulic jacks now incorporate features such as adjustable height settings, built-in safety locks, and user-friendly controls, allowing for quick and easy adjustments even in demanding environments.

One key tip for maximizing the efficiency of hydraulic jacks is to regularly maintain the equipment. Regular checks on hydraulic fluid levels, seals, and hoses can prevent equipment failure and prolong the jack's lifespan. Additionally, ensuring the jack is used on a stable, level surface can significantly enhance performance and safety.

Another useful suggestion is to familiarize users with the specific jack models and their unique features. Training personnel on proper use and safety precautions not only optimizes operational efficiency but also minimizes the risk of accidents. Investing time in understanding the innovative designs of hydraulic jacks can lead to better performance and more effective lifting solutions globally.

When utilizing hydraulic jacks, safety should always be the primary concern. Proper training is essential for operators to understand the nuances of hydraulic systems, including load limits and stabilization techniques. Using a jack beyond its rated capacity can result in catastrophic failure, leading to serious injury or damage. It is crucial to regularly inspect hydraulic jacks for signs of wear, leaks, or deformities before each use. Compliance with the manufacturer’s guidelines ensures that the equipment functions safely and effectively.

Best practices also involve the correct setup of the hydraulic jack. Always position the jack on a flat and stable surface to prevent tipping or sinking. When lifting a load, ensure that it is secure and evenly balanced. Using safety stands or blocks during maintenance or repair tasks is essential to provide additional support. Furthermore, operators should wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to safeguard against potential accidents. By adhering to these safety considerations and best practices, users can maximize the benefits of hydraulic jacks while minimizing risks associated with their use.

The evolution of hydraulic jack solutions is at the forefront of transforming global markets. As industries continue to demand more efficient lifting mechanisms, manufacturers are innovating to enhance the capabilities and applications of hydraulic jacks. Future perspectives suggest that advancements in technology, such as integration with smart systems and the development of lightweight materials, will enable hydraulic jacks to cater to a broader range of heavy-duty applications. This evolution is not only about improving lifting capacity but also about making these tools more user-friendly and versatile.

Tips for selecting hydraulic jacks: First, always assess the specific requirements of your project, including load weight and height adjustment. This ensures you choose a jack that meets your needs efficiently. Additionally, consider those with safety features, such as overload protection and stability locks, to enhance workplace safety. Finally, look out for models that offer easy portability and storage solutions to maximize flexibility in various environments, especially for global suppliers navigating different markets. By staying ahead with these innovative solutions, suppliers can ensure they remain competitive and responsive to changing industry demands.