Empowering Engineering Excellence: Innovate, Elevate, Deliver.

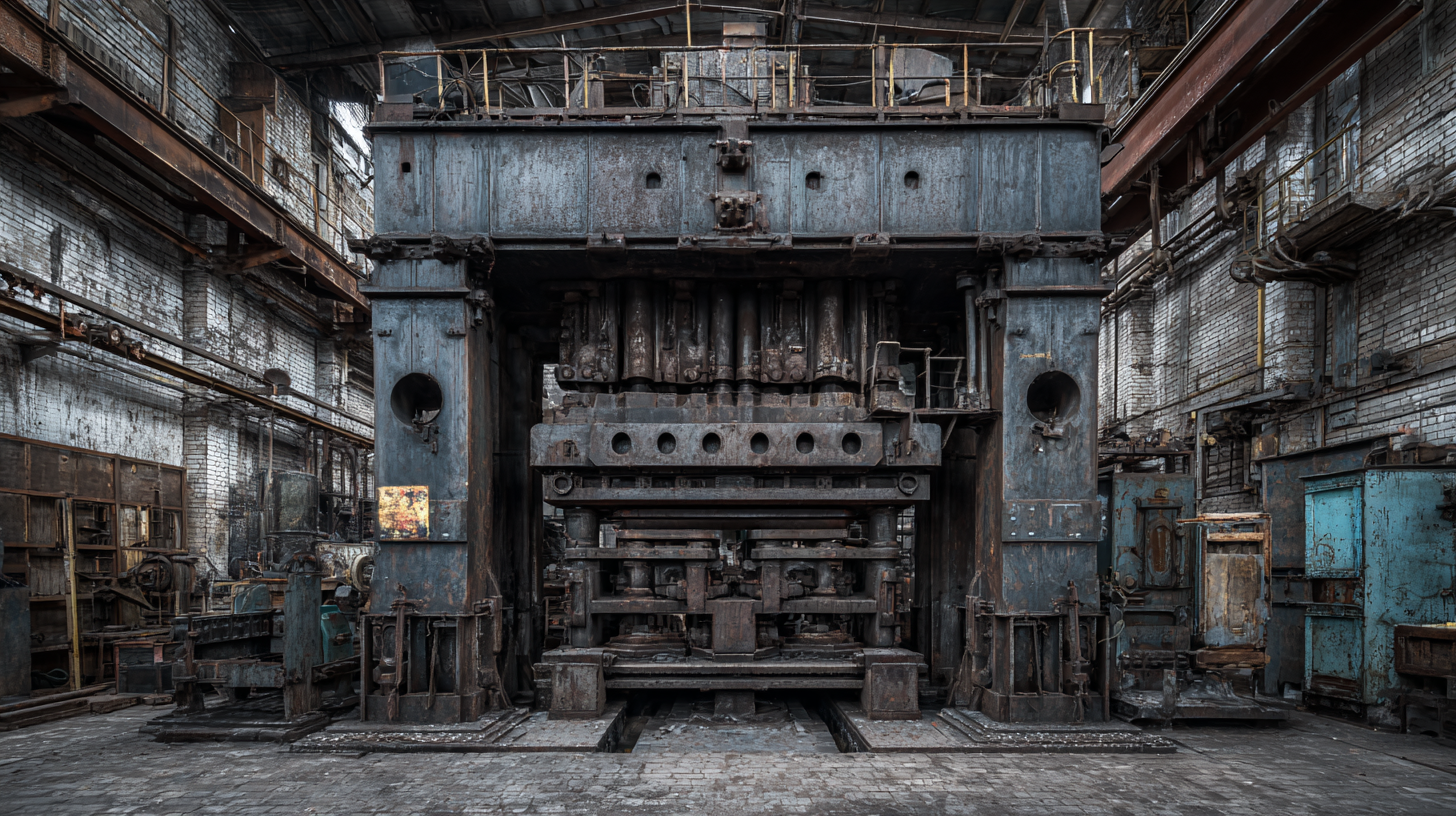

As we move towards 2025, the landscape of manufacturing technology is rapidly evolving, particularly with regards to Hydraulic Press Machines. According to a recent market analysis by Grand View Research, the global hydraulic press machine market is expected to reach approximately USD 10 billion by 2025, growing at a compound annual growth rate (CAGR) of around 4.5%. This surge is driven by advancements in automation, efficiency, and the increasing need for precision in various industries, such as automotive and aerospace. With this growth, understanding the emerging trends and innovations surrounding Hydraulic Press Machines becomes crucial for manufacturers aiming to remain competitive. This blog will delve into the evolving trends of hydraulic press technology, examining the reasons behind their adoption and the impact they hold for the future of manufacturing.

In 2025, understanding the basics of hydraulic press machines is crucial as their applications continue to expand across various industries, including manufacturing, automotive, and aerospace. Hydraulic press machines function on the principle of Pascal’s Law, utilizing hydraulic fluids to transmit force effectively. According to a report by MarketsandMarkets, the global hydraulic press market is expected to reach $4.2 billion by 2027, growing at a CAGR of 4.1% from 2022. This growth underscores the growing importance of these machines in producing parts that require high precision.

Moreover, advancements in technology have led to more efficient designs and intelligent automation features in hydraulic presses. Industry experts point out that integration with IoT devices can facilitate real-time monitoring of performance metrics, optimally balancing energy consumption and output. A recent study by Research and Markets found that 60% of manufacturers plan to adopt smart hydraulic pressing solutions by 2025 to enhance productivity and reduce downtime. As the industry evolves, professionals must stay informed about these fundamental aspects to harness the full potential of hydraulic press machines.

As we look towards 2025, the landscape of hydraulic press technology is being shaped by a multitude of innovations that promise to enhance efficiency and adaptability across various industries. Key developments in electro-hydraulics are particularly noteworthy, as they contribute significantly to the functionality of off-highway vehicles. These advancements are not only improving machine control but are also paving the way for more sustainable practices in equipment operation, aligning with the growing demand for energy-efficient technologies.

Moreover, the introduction of advanced hydraulic press systems is revolutionizing sectors like aerospace manufacturing. These cutting-edge machines are designed to handle increasingly complex materials and processes, thus enabling manufacturers to achieve better precision and productivity. As the industry embraces automation and smart technology, the integration of these innovations into hydraulic press machines is destined to redefine operational methodologies, enhancing both output quality and environmental stewardship. The future of hydraulic press technology, therefore, is not just about power and capacity, but also about integrating smart solutions that meet the challenges of tomorrow's market demands.

The hydraulic press machine industry is experiencing dynamic shifts, driven by technological advancements and changing market demands. In 2025, manufacturers are increasingly looking for machines that not only deliver high efficiency but also incorporate smart technology. This includes features like automation and remote monitoring, enabling users to optimize operations in real-time. As sustainable practices become more critical, the emphasis will likely be on hydraulic presses that consume less energy and utilize eco-friendly materials, aligning with global efforts to reduce carbon footprints.

Furthermore, the demand for customization is reshaping the landscape. Industries such as automotive, aerospace, and consumer goods are seeking tailored solutions that meet specific production requirements. This trend is prompting hydraulic press manufacturers to develop modular systems that can be easily adjusted for different applications. As businesses strive for greater agility and quicker turnaround times, the ability to swiftly adapt hydraulic press configurations will become an essential characteristic of future machines. This evolution reflects a broader shift towards versatility in manufacturing processes, ensuring that companies can remain competitive and responsive to market changes.

In 2025, navigating the evolving trends of hydraulic press machines will require a strategic approach to maintenance and upgrades. The global hydraulic engineering unit market is poised for significant growth, with an estimated market value of $1.47 billion in 2025, increasing to $2.31 billion by 2032. This trend underlines the importance of investing in reliable maintenance practices to maximize equipment efficiency and lifespan. Regular maintenance not only ensures optimal performance but can also prevent costly downtimes associated with equipment failure.

As the industrial hydraulic equipment market is projected to expand from $26.13 billion in 2023 to $35.92 billion by 2030, a compound annual growth rate of 4.7% demonstrates the increasing demand for advanced hydraulic machinery. Keeping hydraulic press machines upgraded with the latest technologies can significantly enhance operational productivity. Companies that prioritize preventive maintenance strategies will likely lead the pack, ensuring their machines remain competitive and efficient while adapting to the dynamic demands of the industry. Implementing best practices in maintenance can lead to sustainable growth and improved operational reliability across the sector.

| Aspect | Best Practices | Maintenance Frequency | Upgrade Consideration |

|---|---|---|---|

| Oil Quality | Use high-quality hydraulic fluid | Every 6 months | Consider synthetic options |

| Seal Checks | Regularly inspect seals | Monthly | Upgrade to advanced sealing materials |

| Pressure Calibration | Frequent pressure testing | Quarterly | Integrate digital pressure monitoring systems |

| Safety Features | Ensure all safety guards are in place | Before every shift | Install emergency-stop buttons |

| Component Inspection | Routine checks for wear and tear | Monthly | Replace outdated or worn-out components |

As the use of hydraulic press machines continues to rise in various industries, adhering to safety protocols and regulations in 2025 is paramount. According to a recent industry report by the National Institute for Occupational Safety and Health (NIOSH), approximately 21% of workplace injuries involving machinery can be attributed to improper safety practices. This underscores the importance of establishing comprehensive safety standards for hydraulic press operations. Operators must be trained not only in machine handling but also in recognizing potential hazards, such as pinch points and hydraulic fluid leaks.

**Tips:** Regularly inspect machinery before use to ensure that all safety guards are in place and operational. Implement a routine maintenance schedule that aligns with manufacturer guidelines to enhance safety and efficiency.

Moreover, compliance with updated regulations from the Occupational Safety and Health Administration (OSHA) is crucial. In 2025, operators should be familiar with the latest guidelines related to personal protective equipment (PPE), which may include enhanced gloves, eye protection, and hearing conservation measures. The report indicates that workplaces that prioritize PPE usage experience 30% fewer accidents involving hydraulic machinery.

**Tips:** Create a culture of safety through training sessions that reinforce the importance of PPE and regular safety drills. Engage employees in discussions about safety protocols to foster a proactive attitude toward hazard prevention.