Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the rapidly evolving landscape of industrial manufacturing, hydraulic fittings have emerged as a crucial component driving operational efficiency and performance. According to a recent market analysis by Research and Markets, the global hydraulic fittings market is projected to reach USD 11.43 billion by 2025, growing at a CAGR of 5.4%. This growth is fueled by the increasing demand for advanced machinery across sectors such as construction, automotive, and industrial equipment. As we approach Industry 2025, technological trends indicate a shift towards smarter and more sustainable hydraulic solutions, setting the stage for Chinese manufacturers to leverage innovation and quality standards to lead the global market. By exploring top strategies tailored to this dynamic environment, businesses can position themselves to capitalize on the significant opportunities presented by hydraulic fittings in the coming years.

The global market for hydraulic fittings has seen a significant transformation over the past few years,

with Chinese manufacturers emerging as key players. This rise can be attributed to their

commitment to quality and innovation, which has allowed them to meet international standards

and compete effectively on the world stage. Chinese companies have invested heavily in research and development,

creating products that not only meet but often exceed the expectations of global customers.

Moreover, the combination of competitive pricing and robust production capabilities

has attracted international buyers who seek quality products without compromising on cost. As global industries continue to expand,

the demand for reliable hydraulic fittings has surged, and Chinese manufacturers are well poised to fulfill this need. Their ability

to quickly adapt to market changes and leverage advanced technology places them at the forefront of the hydraulic fittings market,

signaling a new era of competition and collaboration in the industry.

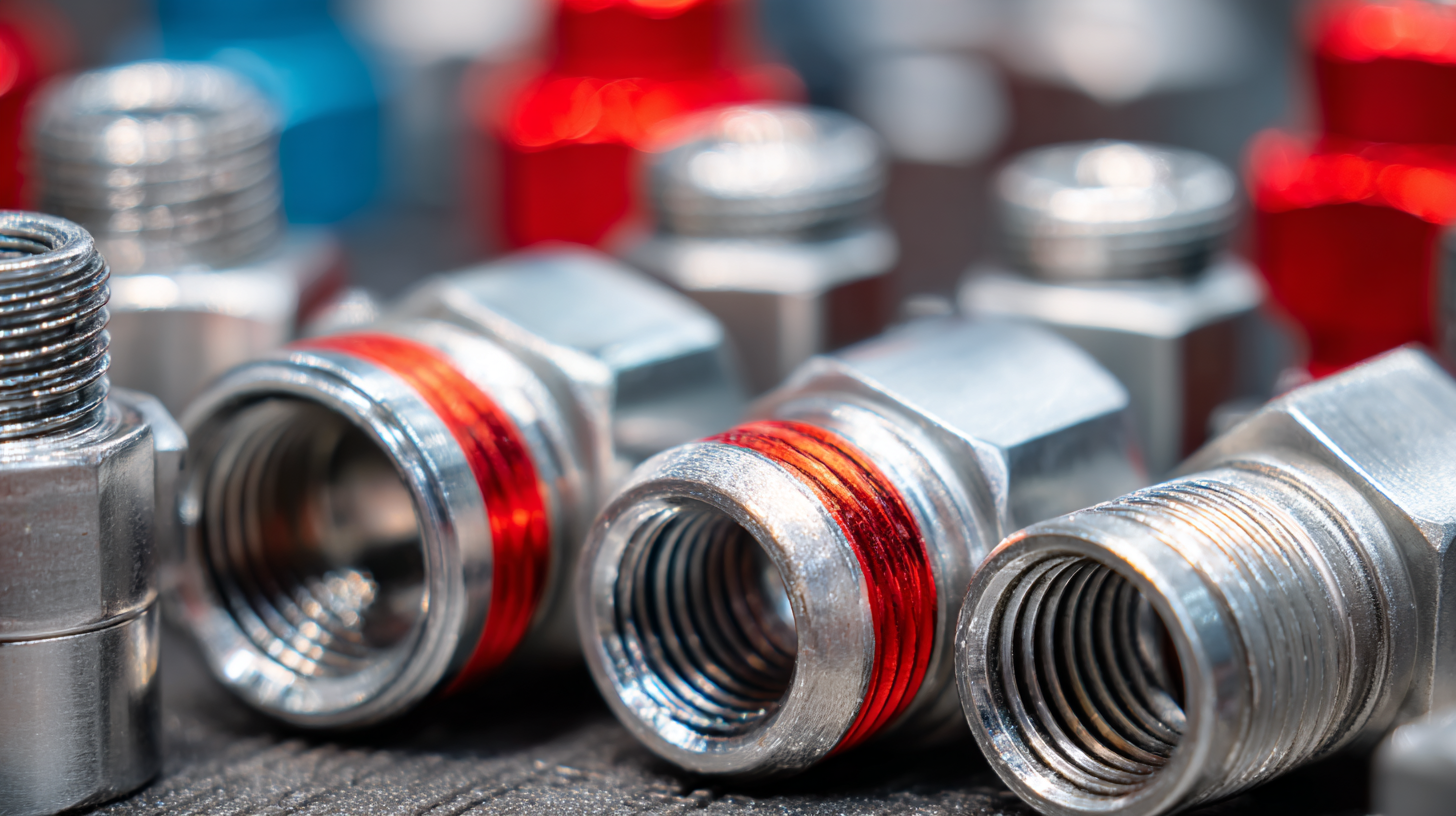

When it comes to selecting hydraulic fittings, understanding quality standards is crucial for ensuring reliability and performance. The key aspects to consider include material certification, pressure rating, and seal integrity. High-quality hydraulic fittings are often made from durable materials like stainless steel or high-grade alloys, which can withstand extreme operating conditions. Ensuring that fittings come with proper certification guarantees that they meet industry-quality requirements.

Tip: Always verify that the fittings you choose comply with international standards such as ISO or SAE. This not only assures durability but also enhances compatibility with other hydraulic components.

Another vital factor is the fitting's pressure rating. Hydraulic systems operate under significant pressure, and using fittings that exceed their rated capacity can lead to catastrophic failures. Each fitting should be clearly marked with its maximum working pressure, and choosing the right fittings based on your specific application is essential.

Tip: Before purchasing, consult with suppliers about the intended application, and ensure the fittings are rated appropriately to handle the expected pressure levels.

Lastly, seal integrity plays a pivotal role in preventing leaks that can compromise both safety and efficiency. Look for fittings that have been tested for leakage to guarantee their performance under pressure.

Tip: Opt for fittings with integrated sealing solutions, as they ensure a tighter fit and reduce the risk of leaks during operation.

In recent years, China's hydraulic fittings industry has made significant strides in innovative technology, positioning itself as a formidable player in the global market. The integration of advanced manufacturing techniques and intelligent automation has granted Chinese manufacturers a competitive edge, allowing them to produce high-quality, reliable products that meet international standards. As industries around the world increasingly prioritize efficiency and sustainability, these innovations are becoming even more crucial in maintaining market leadership.

**Tip:** Embrace a culture of innovation within your organization. Encourage team collaboration and invest in research and development to uncover new technologies that can enhance product quality and performance.

Moreover, the rapid growth of digital economies in China signifies a shift towards smart production methods, which are essential for boosting the industry's global competitiveness. The incorporation of artificial intelligence and big data analytics into manufacturing processes is transforming traditional practices, enabling companies to optimize operations and reduce costs effectively.

**Tip:** Focus on building a resilient supply chain. By leveraging technology and data insights, businesses can enhance their agility and responsiveness to market changes, ensuring they remain at the forefront of industry advancements.

| Year | Market Share (%) | Export Volume (Million Units) | R&D Investment (Million USD) | New Technologies Introduced |

|---|---|---|---|---|

| 2018 | 32% | 15 | 50 | Hydraulic Tube Couplings |

| 2019 | 35% | 18 | 65 | Quick Connect Fittings |

| 2020 | 38% | 20 | 70 | Smart Hydraulic Systems |

| 2021 | 40% | 22 | 80 | Digital Control Technology |

| 2022 | 42% | 25 | 90 | Eco-Friendly Materials |

The hydraulic fittings supply chain has faced significant challenges in recent years, primarily due to global supply chain disruptions and increasing demand from various industrial sectors. According to a report from ResearchAndMarkets, the global hydraulic fittings market is expected to reach USD 3.61 billion by 2027, growing at a CAGR of 6.8% from 2020 to 2027. This robust growth highlights the escalating need for innovative solutions to streamline the supply chain and maintain quality standards.

One of the primary challenges is sourcing raw materials, which has been particularly problematic post-pandemic. The International Organization for Standardization (ISO) reported that fluctuations in material availability can lead to increased lead times and costs, adversely affecting the performance of manufacturers. In response, Chinese companies are leveraging advanced technologies such as AI and blockchain to enhance transparency and efficiency within their supply chains. By implementing real-time tracking systems and predictive analytics, they are better equipped to manage inventory levels and reduce delays, ensuring a reliable flow of high-quality hydraulic fittings to meet the surging global demand.

As the global demand for hydraulic fittings continues to grow, sustainability and efficiency are emerging as key trends shaping the industry. According to a recent report by the International Hydraulic Industry Association (IHIA), the market for hydraulic fittings is projected to reach $23 billion by 2025, driven by the increasing focus on environmentally friendly manufacturing practices. Companies are now investing in sustainable materials and production processes that minimize waste and reduce carbon emissions.

In addition, the integration of smart technology within hydraulic systems is enhancing operational efficiency. A 2022 survey conducted by Global Industry Analysts found that nearly 45% of industry leaders are prioritizing the adoption of IoT (Internet of Things) in hydraulic fittings to improve performance monitoring and predictive maintenance. This technological shift is not only optimizing the lifespan of hydraulic systems but also significantly lowering energy consumption, aligning with global sustainability goals. As we move forward, these trends are set to establish a new standard for hydraulic fittings, ensuring they not only meet the demands of modern applications but also adhere to a more sustainable and efficient future.